Prestige Color Upgrades Offset Operation with RMGT 9 Series

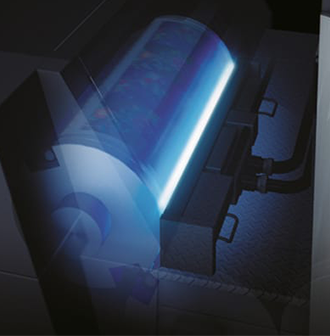

LANCASTER, PA — January 15, 2019 — Prestige Color is proud to announce that they have installed a new RMGT 9 Series five-color offset press with coater and LED-UV curing. The 50-year old business has been owned and operated by Jim Miklos, President, for the past 10 years, doubling in size to a more than $8 million operation. Prestige Color caters to medium and large businesses, providing integrated solutions that provide total document management, digital printing capabilities and online access. The acquisition of the RMGT 9 Series offset press allowed Prestige Color to replace two of their older 40-inch offset presses.

An analysis of their previous offset operation revealed that makereadies were taking up as much as 65% of the charged press time, leading to slow downs and backups as they waited to get work into production. “We had to do something to improve that,” states Jim Miklos. “We addressed other equipment needs first, ahead of the press investment, but it was time for us to make the move.”

Faster makereadies saving dozens of hours monthly

The press was installed in May 2018, and Miklos said it is performing well above expectations. The average makeready on his old presses, he noted, was around an hour and 45 minutes. Today, it is currently 15-20 minutes. Cutting their make readies along with increased press speed has led to a tremendous increase in productivity. “We can do what used to take two shifts in one, giving us room to grow. And we can be much more competitive going after new work,” comments Miklos.

Miklos notes a possible shift in the work that previously went to the digital print side of their operation. He said that one of the next steps for the business is re-evaluating the threshold of what gets produced on which technology. “With LED-UV curing, the rationale to produce print using offset has changed dramatically,” he noted. “Doing a full analysis of our digital workload will be the next big project. We could feasibly move more back to offset and save clicks.”

Saving clicks with RMGT LED-UV Curing

While run length is one of the factors for determining which press to use, Miklos noted that it also depends on what type of finishing is required, as well as how fast the customer needs it. “If a project needs to be done tomorrow, before it would go to the digital press,” he said. “Today I would say we can do it less expensively on the RMGT. I could buy two RMGT presses for what I pay in digital clicks per month, so there is definitely a lot of opportunity here.” He did note that not all work can be driven from digital to offset, but said if he can move even 25% of the work back to the RMGT press, he will see significant savings.

And the savings go beyond the click charges, as well. Because the RMGT press replaced two older presses, Miklos was able to move his flexo equipment from another facility into the space vacated by one of the presses, closing down a second location. He said that was $6,000 a month in savings alone. “All these moving parts have allowed us to save more than the cost to install the equipment,” he noted.

The cutting edge of pressrooms around the country

Another cost savings they have experienced has to do with the reduction of personnel. Previously, he noted, they had five operators running the presses, but today they just have one. “The RMGT now does the lion’s share of the work,” he said. “It was the best ‘bang for our buck’ in terms of value for the investment. And the emerging LED UV technology, in conjunction with the fast makereadies and press speeds, allowed us to jump in and be at the cutting edge of pressrooms around the country.”

“There is a lot of talk about what digital technologies can do, but the click charges can add up fast,” said Jim Lundy, sales manager with G. E. Richards, an authorized RMGT dealer in North America. “With RMGT’s LED UV technology, Prestige Color is proving that short run doesn’t have to mean high-cost digital equipment. There is still a market out there for short and medium length offset jobs, and innovative shops like this one are a great example of how to do it right. We are proud to be part of their journey, and we look forward to serving them for many more years to come.”

About G.E. Richards

Founded in 1972, G.E. Richards Graphic Supplies has grown to 10 branches and over 50 million in sales. They have become the fourth largest graphic arts dealer in the country by keeping in touch with the ever changing needs of their customers and the printing and graphic arts industries. G.E. Richards offers a large variety of products from printing plates, presses and ink, to film, computers, printers, scanners, imagesetters and platesetters.Learn more at www.gerichards.com

About RMGT

RMGT is represented in the US and Canada by a group of six authorized sales and service centers that serve commercial printers, offset packaging converters and in-plant printers in North America. This network constitutes the single largest offset press sales and service team in North America. In 2008, RMGT introduced the first LED-UV printing system for sheet-fed offset printing. Today, RMGT continues to apply their technological expertise and creativity for constant innovation, providing the printing industry with meaningful products and services. Learn more about RMGT at www.ryobimhi.com