microcut® Transcend – Clamp/Cut Control System

microcut® Transcend Clamp/Cut Control System allows any flywheel cyclical paper cutting machine to be brought up to modern standards. The system is a complete clamp/cut control system that can replace an existing control system and is available as an OEM package for new machines.

(The system requires installation of a microcut PLUS WS backgauge control system for the operator interface.)

The microcut® Transcend Control System Components:

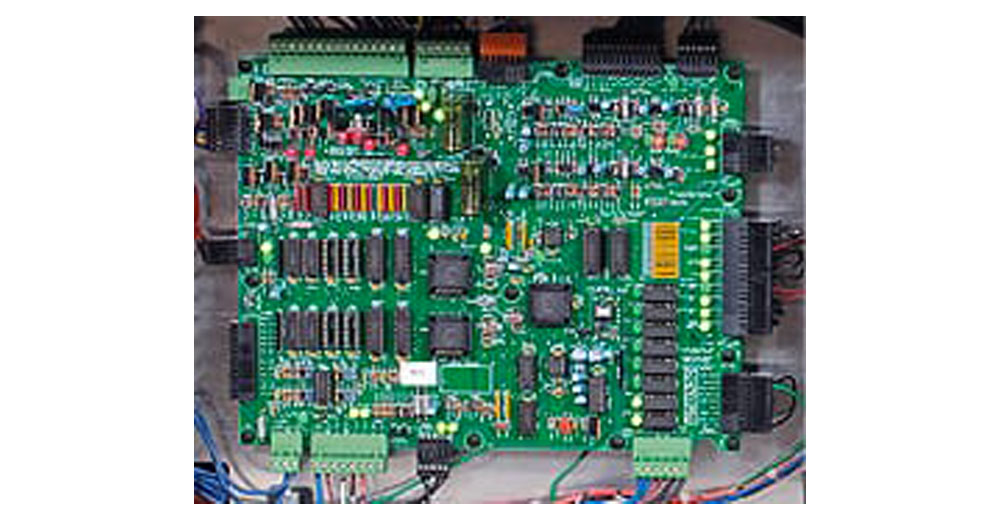

Transcend Control PCB: Controls all clamping, cutting and safety pin operation. Safety and expansion CPUs for monitoring, cross verification and full machine control.

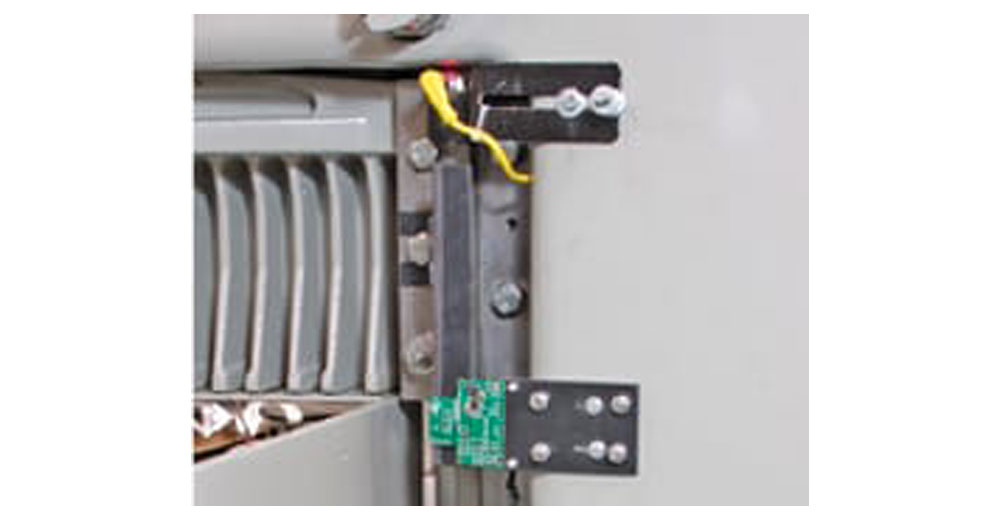

Knife Position Monitor: Monitors and sends knife motion and position status to the control system.

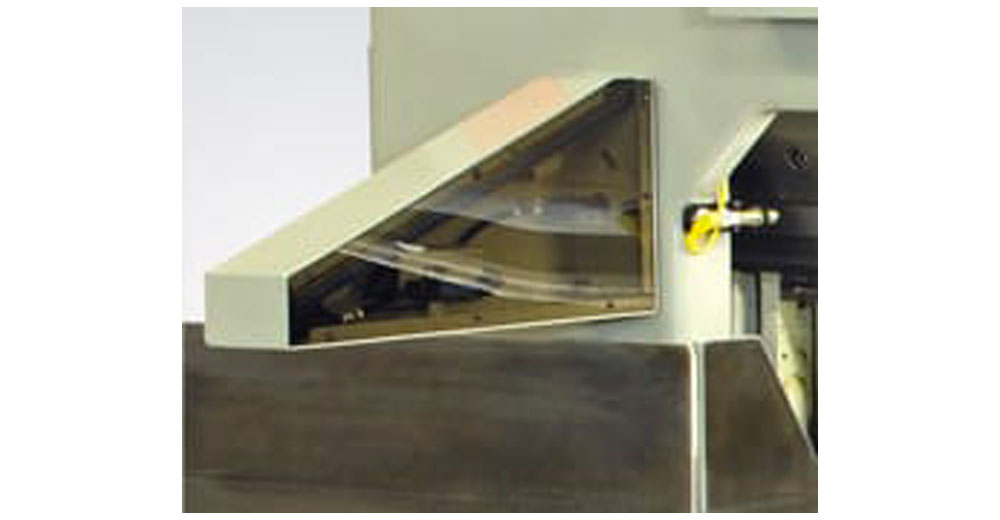

Clamp Encoder Assembly (optional): Monitors clamp motion for clamp lead (knife delay). Can interface to MIS system for paper height computations.

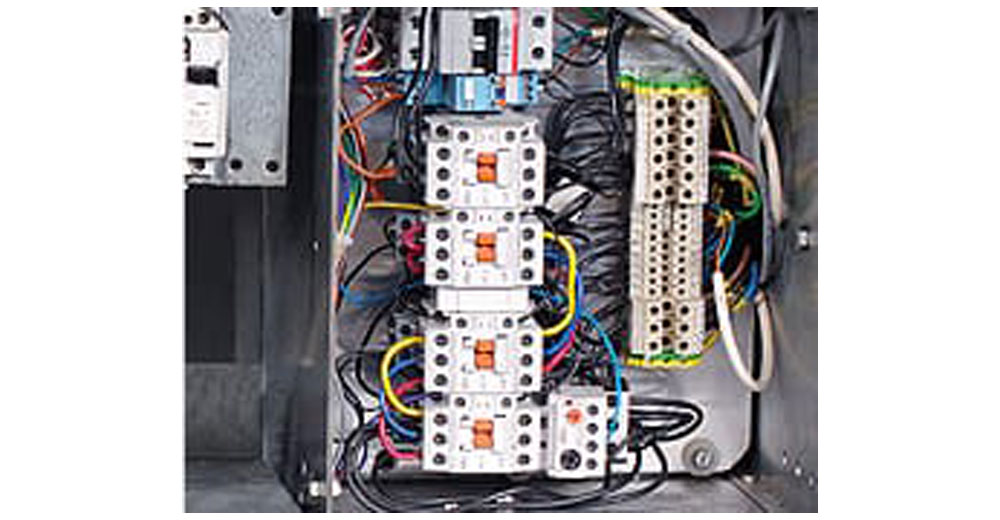

Power panel: Interfaces the AC power components (main motor, air motor) and circuit breakers (H3 drive and DC power supplies).

Safety Curtains: The system can interface with multiple curtain options.

microcut® Transcend Features

- Full machine control with dual channel internal control

- Two independent CPUs

- Two independent oscillator-controlled fail safe channels

- Two independent force-guided relays to control primary drive power

- Cross monitoring

- Full internal safety checking

- Full status and diagnostics shown in microcut® display

- Voltage options for clamp and cut solenoids

- Independent voltage option for safety pin power

- Auto cut option

- Clamp-only option

- Cut optimize operation for machines with independent locking valve

- Programmable clamp pressure

- Auto stop down option for knife adjustment

- Multiple safety curtain options

Additional Inputs for:

- Covers

- Shear bolt(s)

- E-stop

- Foot treadle

- Air paddle

- Autotrim style table full in

- Oil filter

- Open inputs for future expansion

Additional Output Control for:

- Second air zone

- Load control

- Autotrim style table

- Air motor control