Sterling Punchmaster – High-speed Automatic Paper Punching Machine

The Sterling® Punchmaster® is a High-speed Automatic Paper Punching Machine and the paragon of automatic punching, considering its speed and versatility. It will punch for double-loop wire binding, spiral, plastic coil binding, T-slots, or plastic comb binding faster than any automatic punch on the market. It will also punch double row wrap around covers, windows, door hangers, and tags. The machine can punch any shape hole, anywhere on the sheet.

Punch at 130 strokes per minute or 125,000 sheets per hour on the Sterling® Punchmaster®. The machine employs four-way registration to ensure dead on accuracy. The Punchmaster can be pre-loaded while running so that the operator is free to off-load the sheets and deliver them to the binder. The shingling of the sheets on the variable-speed conveyor maximizes efficiency and facilitates quality control. An air feeder is available enabling the punching of: heavy board, signatures, or special stock. A jogger may be added to the system by simply lifting up the delivery tray and placing the jogger at the end of the conveyor. Since the Punchmaster is built in the United States, parts are readily available.

The Punchmaster will punch signatures or single sheets from 4” x 5” cards all the way up to 20” x 22” calendars. Punch a variety of stock such as: paper, board, plastic, vinyl, or leather as well as aluminum sheets.

This machine can handle a greater variety of jobs than any other punch and can produce many products that are die-cut more quickly and cleanly without the need for stripping. It can also punch many jobs that would otherwise have to be punched manually. If you cannot punch it on the Punchmaster, it cannot be punched automatically. Punch it all with the Punchmaster.

Advantages at a Glance

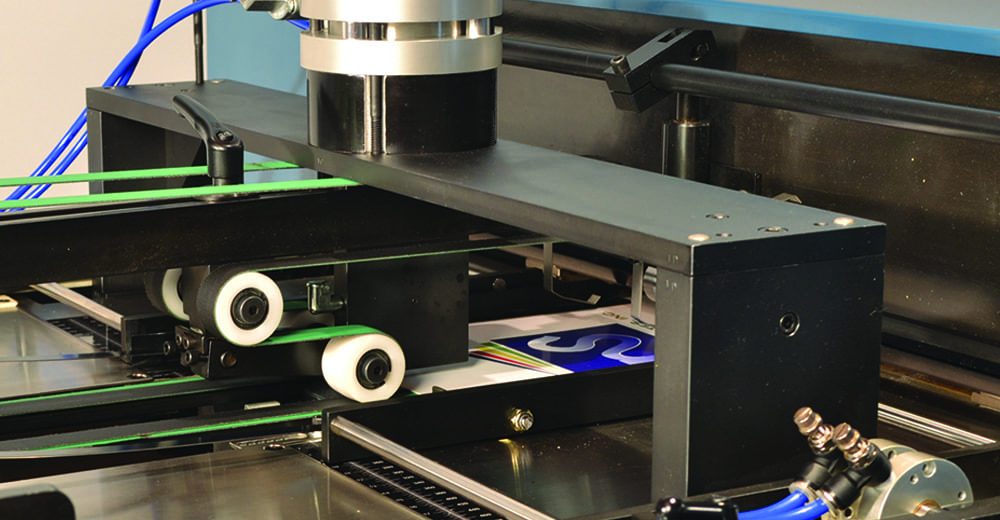

- Stabber: The stabber stabs a lift of paper, adjustable between 2 and 30 sheets, and pulls the paper into the belts irrespective of wave, curl or static.

- Lifter Stabber: The optional lifter stabber lifts the paper prior to stabbing. This is especially useful when punching thicker stock that can split.

- Die: The punch-through die allows for punching anywhere on the sheet, useful for windows, door hangers & wrap around covers. The sheet passes through the die and then into the turn around drum.

- Air Feeder: The optional air feeder is designed to feed signatures, board, plastic, leather, or even pocket folders. It lifts one sheet or signature at a time, prior to feeding it into the belts.

- Calendar Hole Punch Attachment: Punch hanger holes on the face of a calendar while simultaneously punching a hole pattern on the spine of the sheet. This option can be retrofitted to existing Punchmasters.

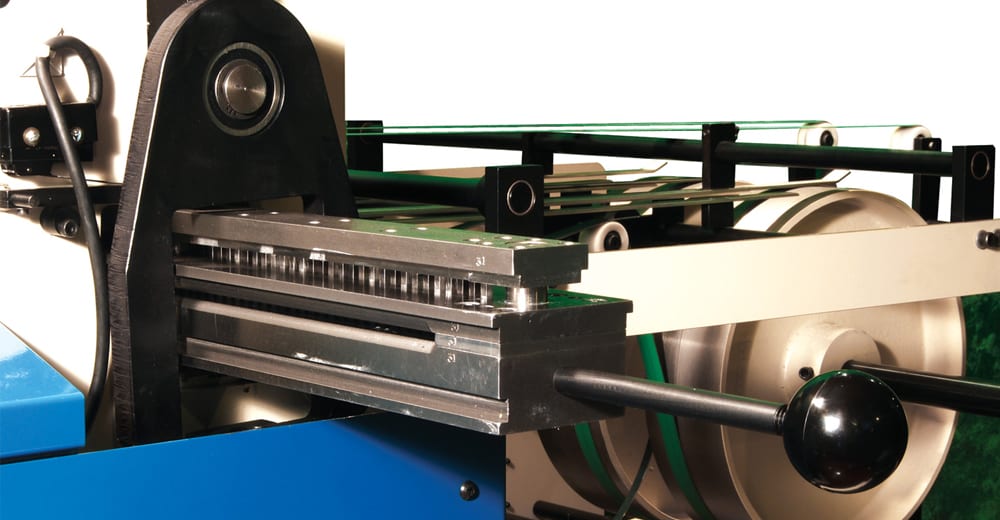

- Micro Die Adjustment: The patented Micro Die Adjustment allows you to “fine tune” the centering of a sheet. It can move the die side-to-side in increments less than .010” (.25 mm).

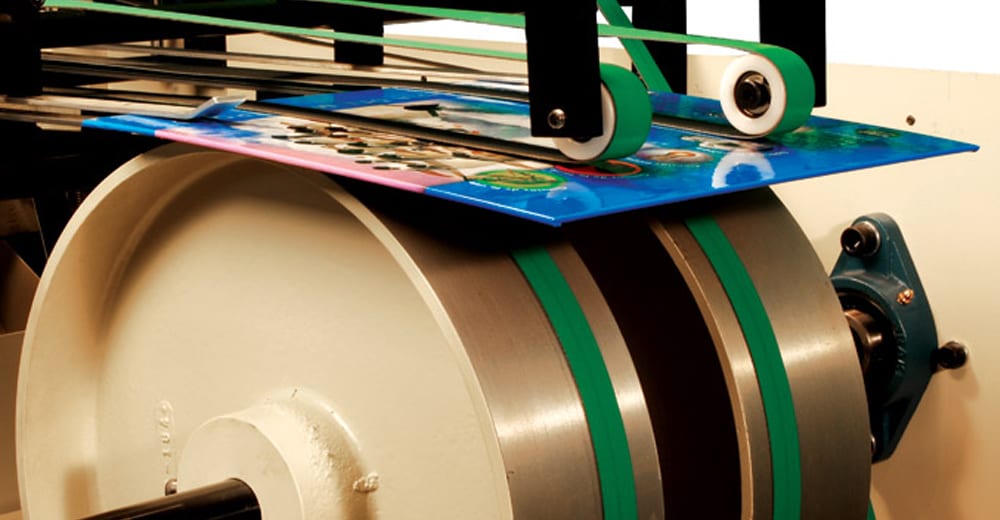

- Drum Bypass: The optional drum bypass is a belt changeover system for heavy board. This will enable the sheet to be delivered without having to bend by traveling around the drum.

- Corner Perforation Attachment: Punch corner perforation holes while simultaneously punching a hole pattern on the spine of the sheet. This option can be retrofitted to existing Punchmaster machines.

Product Information

| Minimum Sheet Size: | 4” x 5” (20 cm x 12 cm) |

| Maximum Sheet Size: | 20” x 22” (50 cm x 55 cm) |

| Speed: | Up to 130 strokes per minute |